The starting point: Sto SE & Co. KGaA is one of the world’s leading manufacturers of products and systems for coatingbuildings. The company is the market leader for thermal insulation systems. Its core business also includes high-quality facade systems as well as plaster and paints for the outside and inside of buildings. Alongside this, it offers products for concrete restoration, floor coatings and acoustic façade systems.

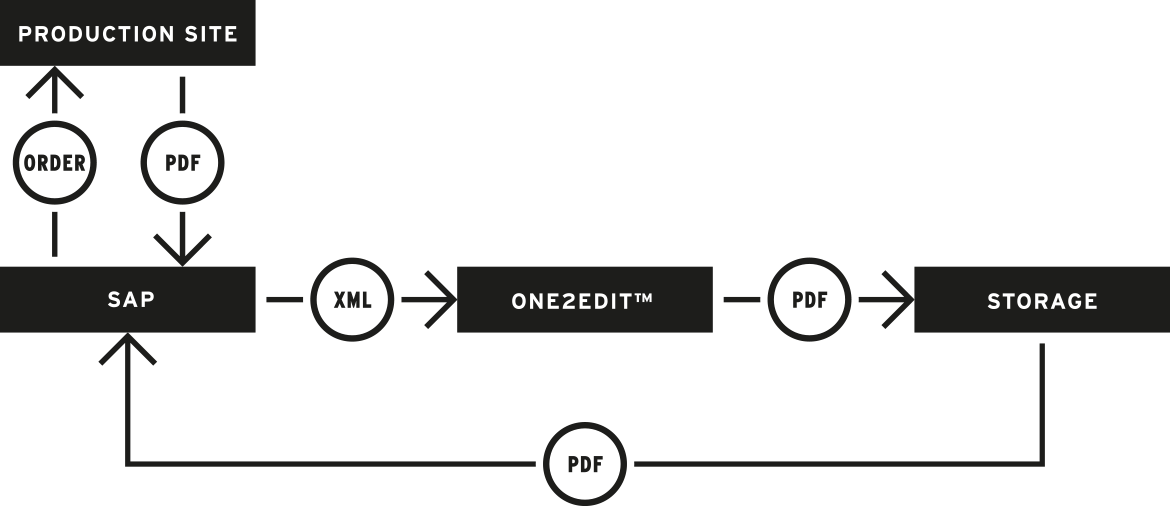

When requirements for the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) were integrated into European Union law, Sto had to deal with significant change. All of its product labels had to be adapted to comply with the new CLP (Classification, Labelling and Packaging) regulations in the EU.

The task: To meet all regulatory requirements without making production processes slower or more expensive – and while maintaining or further improving brand consistency.

The challenge: To develop a cost-effective and time-saving way of generating product labels, including regional versions with different content, sizes, formats and languages.

Performance

Performance